Gallery

Custom Work on Ethan's Yamaha. Main Tuning Slide and F Slide Reversed.

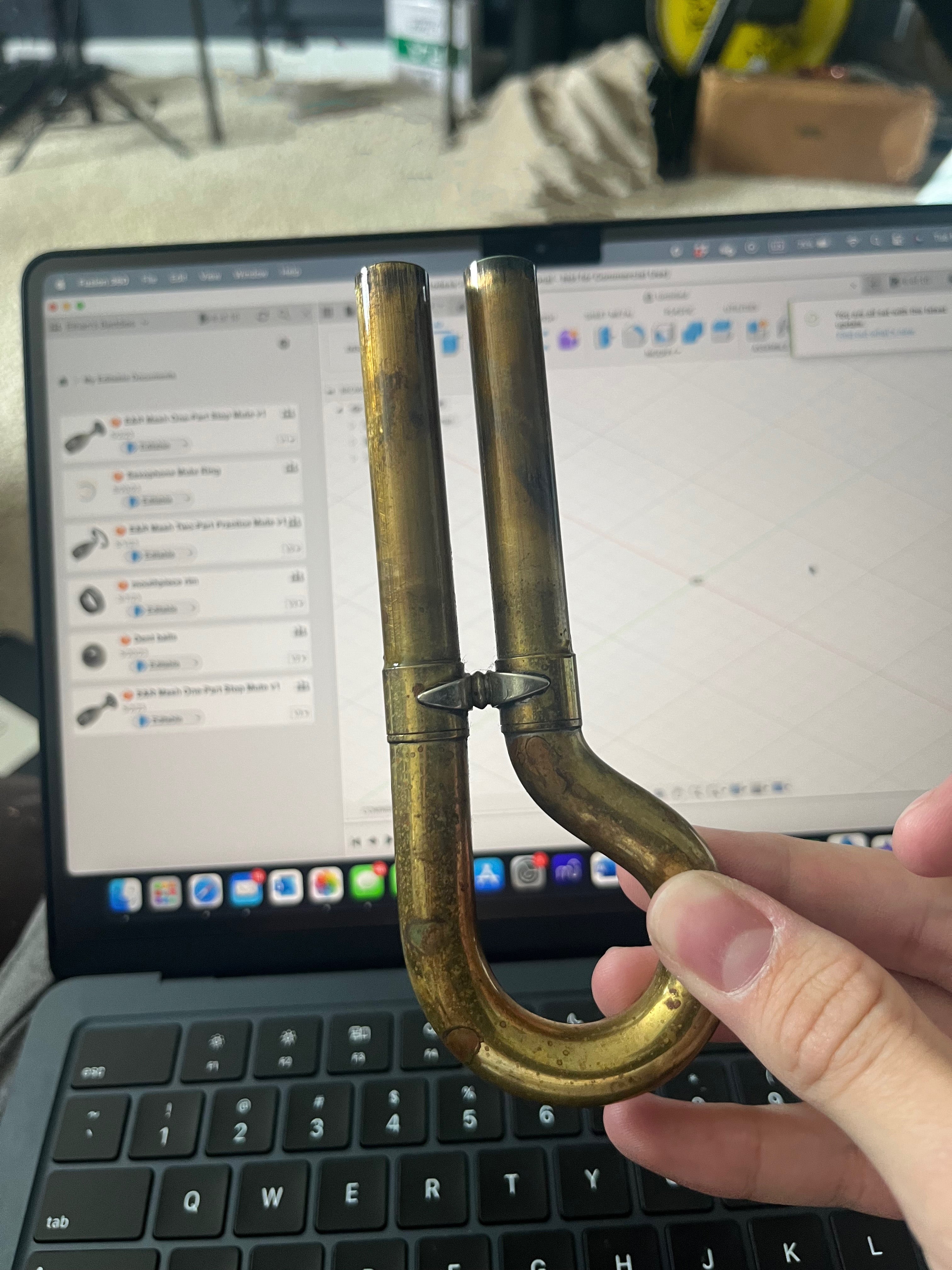

Disassembled and cleaned up slide assembly

Finished customization. Both slides are reversed and perfectly aligned so there is no stress. Custom brace-work connecting the short f-branch to the first-branch. This customization is one that we highly recommend for at least all Yamaha players. It makes the horn incredibly responsive and free blowing. Partials slot more gently, and a more fluid sound is possible. A quote from those who have tried it is that "you just have to think the note and it will come out." This is of course not a magic customization, but it will enhance the sound and precision of your playing.

Cleaning, Polishing, and Making a New Slide For a Hatch Horn

A new top portion of the slide was fabricated. The slide legs, ferrules, and brace were kept original. Everything is cleaned up, but not soldered yet. The slide is put into a precision resin 3D printed form to hold the legs parallel for soldering.

The slide is finished with a singular pull knob added. I find this to be the most comfortable thing to pull out the slide with.

Slide put into horn before it is cleaned and polished to ensure a perfect fit. This slide is longer and, in doing so, more in tune than the original one, which had to be pulled out some ways to be in tune. This may have negative effects on how notes that use that slide feel to play, so we fixed it.

Before and after the horn was cleaned, polished, and made a new slide. Upon receiving their horn back, the customer said "I can’t thank you enough for the work you did on my horn! It feels and sounds terrific, and I can’t get over how stable my high b flat is!" The shepards crook design of many first Bb slides negatively impacts the notes played on that slide, especially when the curve is as severe as this one. A straight slide gives a more stable feel and better intonation.

Mt. Vernon Bach Leadpipe Change Back to Original

Leadpipe that was recently installed by another tech

Original pipe next to the newer one

The horn after the leadpipe was removed

Newer pipe polished for the customer so they could list it for sale

Finished installation of original pipe

Finished installation of new pipe

Removing a Deep Dent On Edwards C Trumpet 3rd Slide

Dent removed from 3rd slide

Slide photographed from another angle to show invisible repair.

Fixing a Crushed Second Valve Slide On An Old King Trumpet

All dents completely removed and slide returned to round. The little remaining lacquer cracked off while working due to the age of the instrument and the severity of the dents.

Removing a Dent From a Ron Pinc Leadpipe On An Original Geyer

Dent is invisible. These dents are very tricky because they are on tapered sections of tubing, and so require more finesse to work on.